RFID Cold Chain Asset tracing management

RFID is an acronym for Radio Frequency Identification which meansRFID is the wireless, non-contact use of radio frequency waves to transfer data and identify objects, animals or humans. RFID systems are usually comprised of an RFID reader, RFID tags, and antennas. RFID is widely used in industries like healthcare,retail,hospitality, and manufacturing.

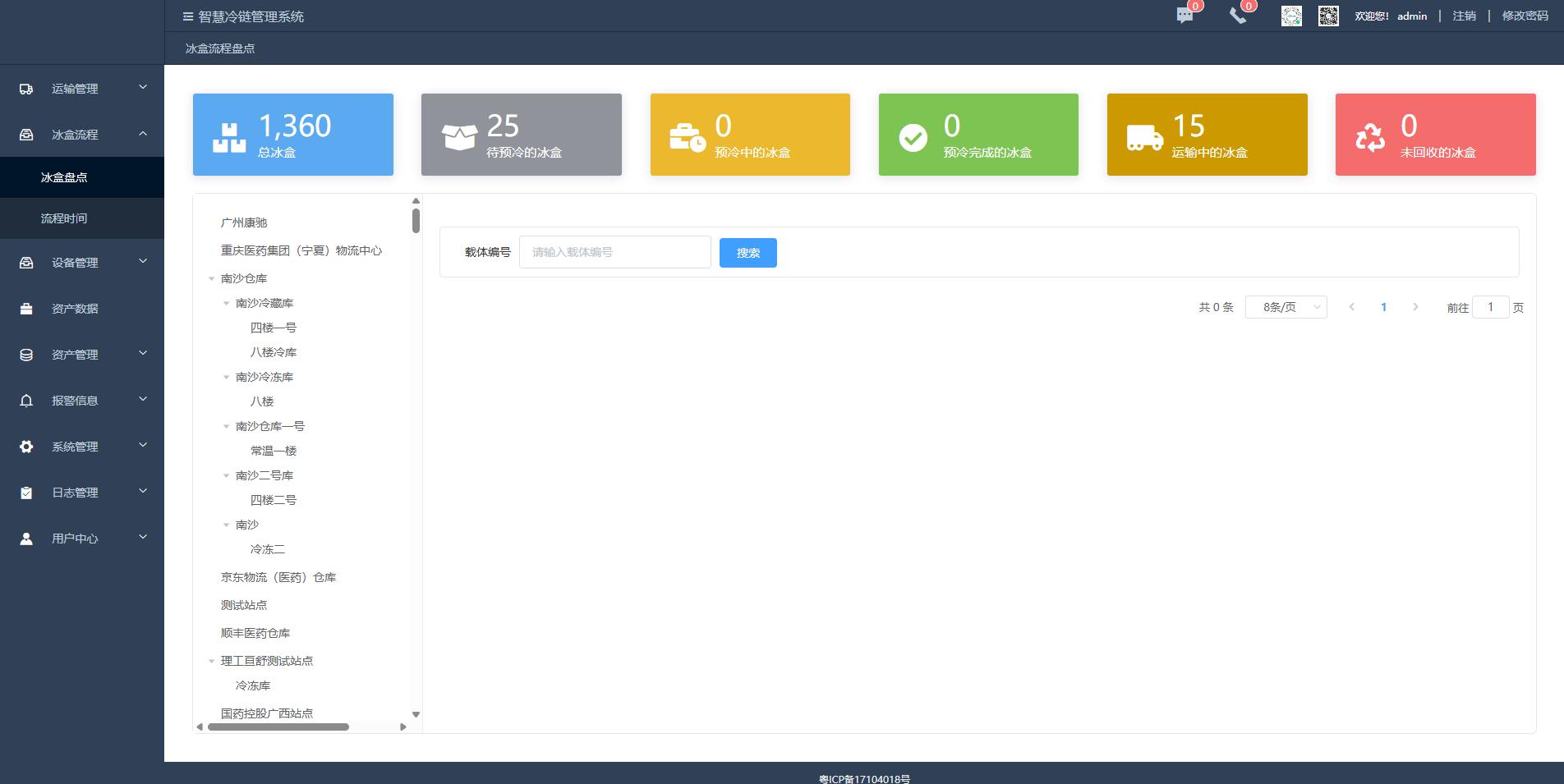

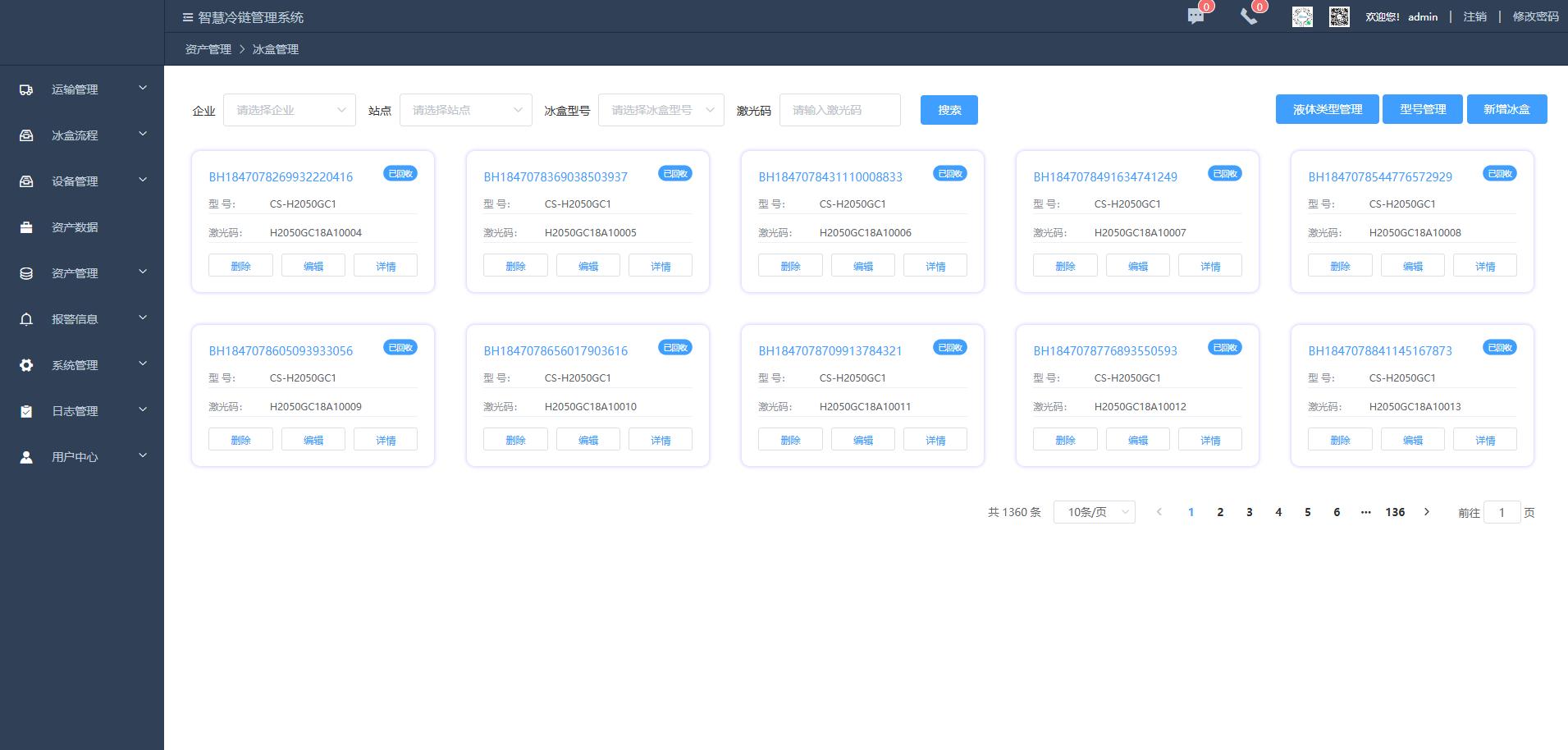

RFID Cold Chain Asset Management System, developed by Guangzhou Cesin Cold Chain Technology Co.,Ltd, is designed specifically for pharmaceutical cold chain logistics scenarios, through sticking the RFID tag on the insulation shipper, ice packs, temperature recorders and other assets with assigned tracking code, set up standard operation SOP reminders to improve the efficiency of inventory management, operation standardization and quality management traceability.It supports the interconnection of all data and information with the owner's cold chain management system.

RFID Cold Chain Asset Management System, developed by Guangzhou Cesin Cold Chain Technology Co.,Ltd, is designed specifically for pharmaceutical cold chain logistics scenarios, through sticking the RFID tag on the insulation shipper, ice packs, temperature recorders and other assets with assigned tracking code, set up standard operation SOP reminders to improve the efficiency of inventory management, operation standardization and quality management traceability.It supports the interconnection of all data and information with the owner's cold chain management system.

Function

• Identification and trace,ensuring the accuracy of association of cCold chain asset.

• Inventory management,monitoring the inventory.

• Operation Alert and control.

• Process management and Alert, Optimizing the test process and improving work efficiency.

• Instrument and equipment quality management: Recording the usage.

• Instrument and equipment quality management: Recording the usage, maintenance history and other information of instruments.

• Inventory management,monitoring the inventory.

• Operation Alert and control.

• Process management and Alert, Optimizing the test process and improving work efficiency.

• Instrument and equipment quality management: Recording the usage.

• Instrument and equipment quality management: Recording the usage, maintenance history and other information of instruments.

Feature

• Contactless automatic identification: No manual intervention is required to improve efficiency.

• Durability: Can be used in various environments.

• Large-capacity storage: Can store a large amount of information.

• Durability: Can be used in various environments.

• Large-capacity storage: Can store a large amount of information.

Case

---------------------------

Industry pain points

———

There are various models of cold chain products, causing difficulties in management,

statistics,confusion, and loss.

———

Frequency, duration, and lifecycle of ice pack

usage are uncounted and unmanageable,making

it difficult to control the quality.

———

Manual recording of ice pack energy storage

and defrosting duration is prone to errors,

frequent issues with insufficient storage and

excessive cold release.

———

Without ID or usage records for the ice pack,it is

impossible to trace the source when the over temperature of the cooler box issues.

Solutions

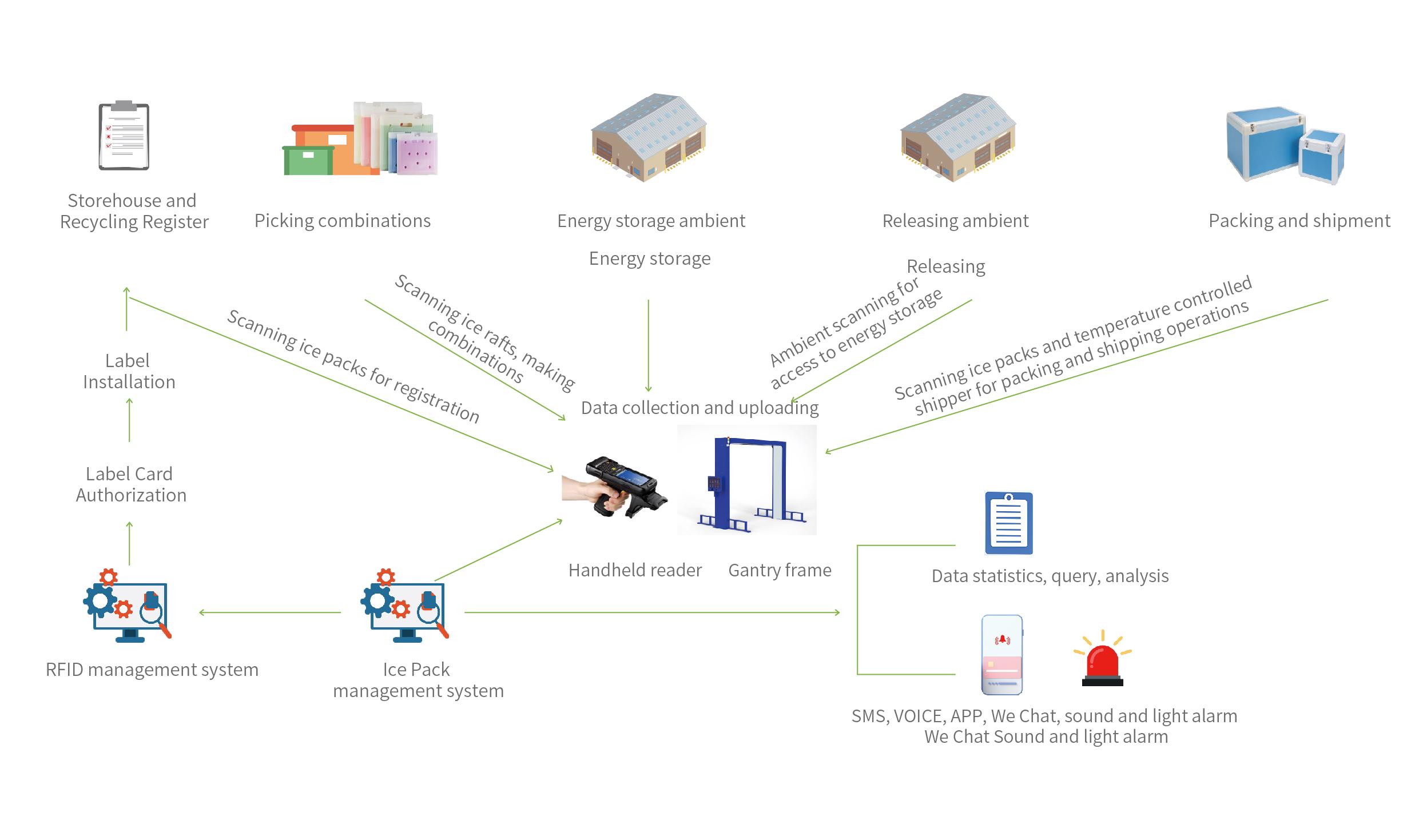

1、Fully associating cold chain products with individual ice pack, cooler box and logger creates an electronic tracking form.

2、The serial numbers of ice packs,cooler boxes and loggers are bound to unique RFID IDs. By integrating with handheld RFID terminals, customized apps and an intelligent cold chain management system, which enhances information integration and simplifies operations.

3、The process-oriented management ensures that the use of ice packs and cooler boxes complies with SOP conditions, also ensure the completeness of recovery as well as the supper vision of the process.

4、Alarm only during transportation to avoid invalid and erroneous information.

5、Differentiating user and data permissions based on enterprises and sites simplifies the process of setting sensor permissions, facilitating simultaneous use by users from multiple organizations.

2、The serial numbers of ice packs,cooler boxes and loggers are bound to unique RFID IDs. By integrating with handheld RFID terminals, customized apps and an intelligent cold chain management system, which enhances information integration and simplifies operations.

3、The process-oriented management ensures that the use of ice packs and cooler boxes complies with SOP conditions, also ensure the completeness of recovery as well as the supper vision of the process.

4、Alarm only during transportation to avoid invalid and erroneous information.

5、Differentiating user and data permissions based on enterprises and sites simplifies the process of setting sensor permissions, facilitating simultaneous use by users from multiple organizations.

Procedure